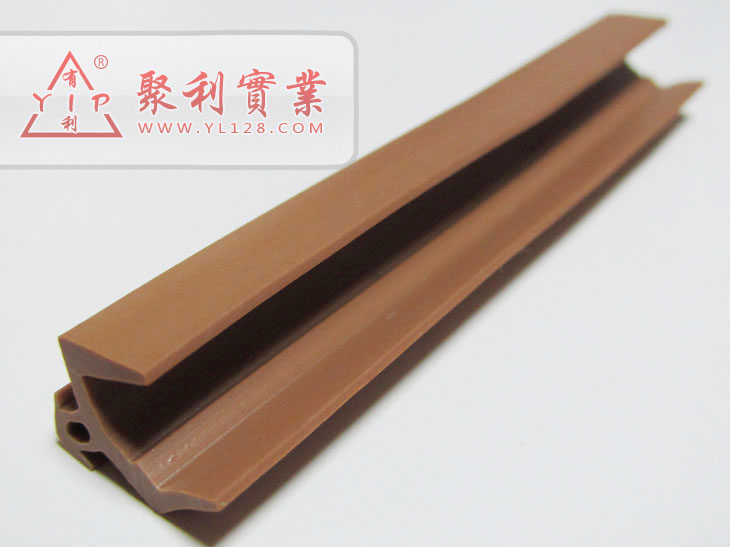

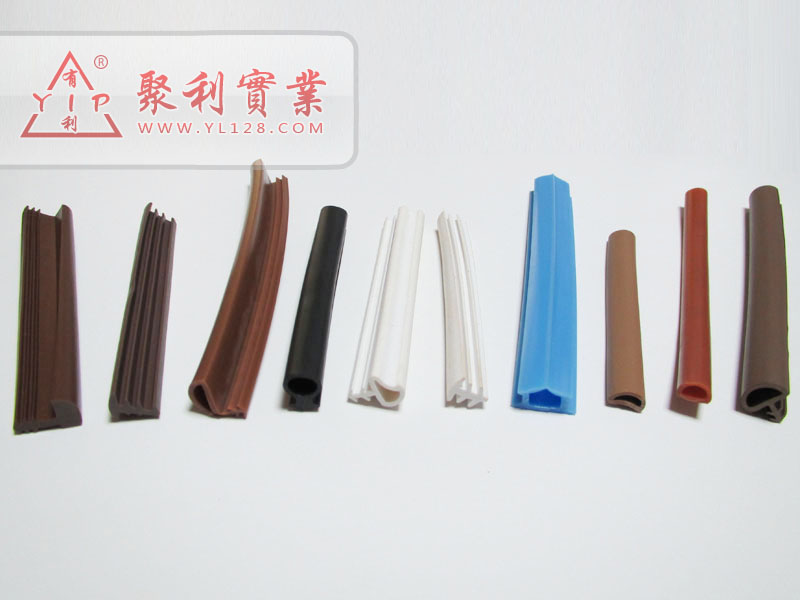

Edge banding is mainly used for furniture, kitchenware, office, door, glass industry, decoration and other products. The main materials are PVC, PE, TPR, TPU. Plastic is easy to process and has plasticity. It deforms after heating and pressing, and maintains its original shape after cooling. It can be processed into various shapes of edge banding by extrusion. There are many types of edge sealing clauses, many shapes, T-shaped, P-shaped, such as glass clip strips, door and window edge strips, stationery edge strips, protective anti-collision strips, etc.

Plastic edge banding has the following advantages

1. Not easy to rot, not easy to rust, non-toxic, tasteless and environmentally friendly, not hard in winter, it has beautiful, decorative and protective effects on the product

2.Compared with wood, glass and other materials, it is light weight and easy to install

3. It has the advantages of heat resistance, oil resistance, strength, high bendability, good toughness, etc., which promotes the widely used PVC edge banding in real life.

4. Edge bands are of high quality and low price, and the price of plastic is far less than that of metal.

Juli Plastic Industry Co., Ltd. has been manufacturing edge banding for 30 years. It is a professional manufacturer or custom of various edge banding on the market. It has accumulated rich production technology experience in the industry, We have rich practical experience in production control, and it is our direction to produce high-quality, environmentally friendly PVC edge banding. Welcome new customers to inquire!